When it comes to printing, paper finish is an important consideration for designers. Unlike web design, print is a three dimensional, tactile medium. It stands to reason that the way a paper feels is going to have an impact on the overall results of the print design. The finish of a sheet (i.e.—its texture) imparts an unspoken message about the piece.

For print projects like packaging, identity and catalogs, it can either enhance the brand message or directly conflict with it. And that point is magnified in the absence of color. When it comes to paper finish for white papers, there is more than meets the eye.

WHAT IS PAPER FINISH?

When we talk about a paper’s finish, we are referring to the tactile feel of the sheet itself. Paper comes in a pretty wide range of finishes, with Smooth Finish often being the default finish, but even among Smooth Finish papers there can be a big difference from mill to mill.

Paper finish has an impact on the printability of a sheet. Typically, the smoother the sheet, the harder its surface is, and that affects ink holdout. In general, you want the ink to sit upon the sheet and dry by oxidation rather than soaking into the sheet and drying. Inks achieve greater levels of gloss and better image quality when they dry on the surface of paper, rather than when they are absorbed.

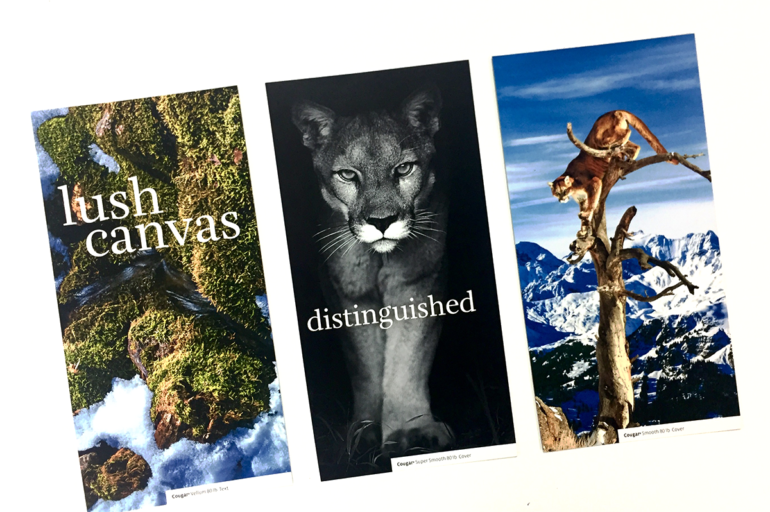

Paper’s smoothness is measured by the Sheffield scale, the lower the number, the smoother the sheet. For example, Cougar 80 lb. Text, Super Smooth Finish has a smoothness of 60, while Cougar 80 lb. Text, Vellum Finish has a smoothness of 110.

PAPER FINISH AND WHITE PAPERS

Most of the papers used for commercial printing tend to be white. When it comes to adding color to print, most projects impart color with ink rather than through paper color. That being said, the finish of the sheet plays a part in how well the colors will look once printed. Paper finish is even more critical when printing heavy areas of solids or metallics, the smoother the finish, the more uniform the ink lay. The more texture the paper finish has the greater the likelihood for ink variation.

Papers with a Super Smooth Finish are great options if you are looking to achieve consistent ink coverage and crisp, vivid images. Their smoothness enhances the moodiness of duo-tones and provides depth and richness to blacks.

Papers with Smooth Finishes give excellent print results while providing a bit of tactility to the piece itself. The Smooth Finish has become the somewhat unspoken default finish of uncoated papers. In the sample department, it’s a given when someone specs Cougar and doesn’t specify the finish that they mean Cougar, Smooth Finish. It’s one of those finishes that is tried and true and works well with several print techniques. An uncoated paper with a Smooth Finish is a great option for projects where a dull or matte coated paper would have been used in the past. It implies a soft, approachability to a brand’s message, something that can be difficult to achieve on slicker coated papers.

Vellum finishes are often described as “toothy feeling” papers—they have a rougher texture to them than a Smooth Finish. This finish is a favorite among the design community as it allows for good printability without sacrificing the natural feel of the sheet. Papers with a Vellum Finish are great choices for stationery items as they impart a feeling of authenticity and connection between the sender and recipient—an essential part of correspondence.

When it comes to white papers, there are also numerous textured finishes known as embossed finishes. The finish is achieved by using pressure to emboss a pattern onto the paper after it has been made. Some of the more recognizable embossed finish patterns include linen, felt and laid, any of which can extend messaging if used properly; for example, a linen finish paper for the cover of a textile product catalog subtly implies the product’s context.

It’s important to restate a point I made at the beginning of this post: many paper mills offer the same name of finishes (a Smooth Finish, for example), but the quality and results can vary greatly. I think it’s always a smart idea to order paper samples before going on press to ensure results are what you and the client expect. The same goes for print samples—if you don’t know how a certain technique will perform on a specific paper finish, ask the mill for a print sample demonstrating the combination. This will help eliminate the guesswork and put your mind at ease.

Discussion