Once thought of only as a solution for short runs, digital printing now has many benefits that make it a serious contender in a brand’s media mix. From personalization via variable data, to attention-getting techniques, to better-than-ever print quality, incorporating well-conceived digital print into your communication materials is a great vehicle to engage customers and tell your brand story.

The biggest mistake we see with digital print stems from poor project planning. Often, a print project is designed without consideration to how the piece will be printed. This is a big mistake! By not thinking ‘digital print’ at the beginning of what turns out to be a digital print project, you run the risk of being disappointed with the outcome and missing out on many of the great benefits digital printing has to offer. To get the most out of digital print, the design and flow of the project should be adjusted accordingly.

Here are our tips for project planning your next digital print project:

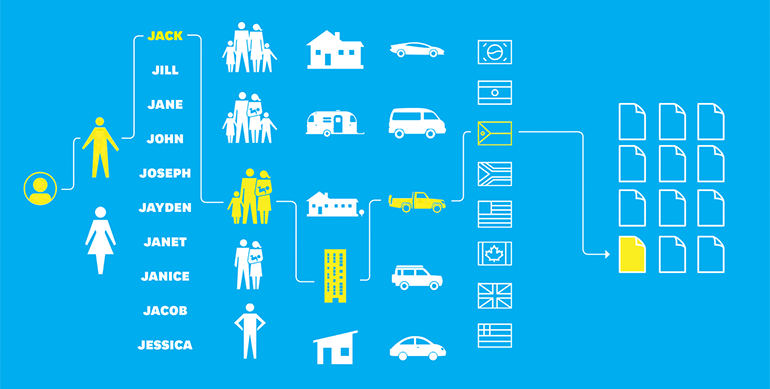

1. Know Your Audience (and use your data) – Knowing your audience is a must for any print project, but it’s imperative to get the most out of digital print. One of the biggest advantages of today’s digital printing technologies is the ability to customize the printed piece for the recipient using variable data—and the customization can go further than “insert recipient’s name here.” These days, if you have the right data, variable imaging can be used to customize the printed piece to the recipient’s preference. For example, an order can arrive with a printed piece featuring products the customer looked at online but didn’t purchase. Or, a catalog can arrive only featuring images of products that are similar to past purchases. The concept is similar to Facebook ads, but print has the benefit of adding brand messaging (and being less creepy).

2. Get to know your printing equipment – the type of printing technology used should be considered at the beginning of any print project for best results. Why? Between offset, digital and inkjet, there’s a wide variety of printing equipment used today, all of which use different types of inks and react differently with different papers. With digital printing alone, different ink and equipment combinations can lead to a slightly different feel and appearance. For example, you might notice some machines will leave a shinier finish on the printed piece, while some look (and feel) more matte. These final results have an impact on the result of the design. To prevent unwanted surprises, the best thing to do at the beginning of a project is to get a few printed samples from your printer. That way, you’ll get a better idea of what to expect from the final piece.

3. Avoid a print disaster – Today’s newer digital presses (if they’re using paper designed for digital printing) print solids beautifully without streakiness and print over folds without cracking, as long as the piece is scored and folded properly and folded with the grain. But, the reality is not every printer has the latest digital printing equipment.

This is another case where printed samples from your printer at the onset of a project can be your best friend. For example, if you notice cracking along the edges of a fold in the printed samples you receive, you might instruct your printer to score and fold with the grain, choose a lower paper weight—or you may choose to be extra cautious and avoid ink coverage on a fold altogether. If you notice streakiness in large solid areas, adding a subtle pattern is a great solution.

4. Use a paper designed for the printing equipment – Although the capabilities of digital printing equipment have advanced in recent years, one adage remains: for superior results, choose a paper that’s specifically engineered for the type of digital printing equipment being used. What that means in non-technical speak is this: there’s a lot of digital printing equipment available today, and the inks they use are all very different from one technology to another.

Having a strong project planning process will help avoid printing disasters. Choosing a paper that’s built for specific equipment, will also improve your project planning success. you have a better chance of NOT disappoint when you receive the final results from your printer and NOT disappointing your client with the print quality, longevity and performance of the printed piece.

Discussion